By its' very

precise nature, memory can be influenced by its surroundings in ways which can

equate to decreased performance and reliability. A few obvious influencers are

of course module temperature and clock frequency, but at lest one other factor

surfaced during our tests of a few SDRAM sticks.

By its' very

precise nature, memory can be influenced by its surroundings in ways which can

equate to decreased performance and reliability. A few obvious influencers are

of course module temperature and clock frequency, but at lest one other factor

surfaced during our tests of a few SDRAM sticks.

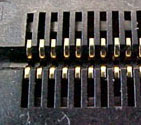

Interestingly, the way memory modules are inserted into the DIMM slot, the

quality of the DIMM socket, and the quality of the module PCB can all influence

the performance of memory very substantially.

In the case of the Ramcheck the differences

in memory module PCB quality were emphasized rather than shortcoming in the

Yamaichi 168-pin socket (IC438-1-1). What we observed were seemingly unrelated

differences in a particular stick of memory that would alter the results of the

Ramcheck's tests for no apparent reason.

The only change in the test procedure was

the removal and reinsertion of the memory module into the DIMM socket.

Otherwise, all settings were left the same. Still, some 168-pin modules would

generate outright errors, while others could be tested in the same fashion and

return entirely consistent results from test to test.

What would be causing a few 168-pin modules

of memory to generate such inconsistent results?

The answer as we

discovered, was due to the minute difference in the tolerances of the underlying

PCB, the green coloured fiberglass backer with copper trace lines supporting the

TSOP-II memory chips. Apparently the differences in conductivity between the

connector pins and the socket pins is to some degree relative to the force

between the two.

The answer as we

discovered, was due to the minute difference in the tolerances of the underlying

PCB, the green coloured fiberglass backer with copper trace lines supporting the

TSOP-II memory chips. Apparently the differences in conductivity between the

connector pins and the socket pins is to some degree relative to the force

between the two.

In some instances we were able to recreate

memory instability by just installing the memory module in the socket with a

small force towards one side. Depending on the tolerances of the PCB, and to

what thousandth of an inch the PCB was thick, or long, there would be minor

differences in the electrical conductivity between socket and pin.

In a few instances of generic memory, the

variances in electrical conductivity were large enough to cause the memory

module to fail the test with error bits. By the same token, the problematic

parameters were so variable that installing the same stick with slight force

toward the other side of the socket could cause no issues whatsoever.

A simple check for quality:

It was interesting to see the results of

lower quality PCB on the performance and stability of a stick of SDRAM and the

only advice we can give you is as follows. Look closely at the left, right, and

bottom edges of the PCB. If it has been machined flat you are probably looking

at some decent parts. If on the other hand it is not totally flat, or appears as

though the PCB may have been scored and broken clean, then you are probably

looking at a lower quality part. Keep in mind that is a rough guide line and won't

hold true for ever instance. Also, since there is no quick and easy way to

measure the thickness of the PCB and gold plated copper trace lines there is no

real simple way to gage quality there.

Of course the other end of the spectrum is

true to. If the motherboard manufacturer uses a less expensive socket with lower

tolerances or less than ideal gold plating on the contact then you may also be

fighting some problems that not stick od DRAM will be about to

circumvent.