Ever wonder how an LED light bulb is made?

Not the tiny coloured lights, but the big, bright, solid state

light bulbs gradually replacing incandescent and compact fluorescent

lighting everywhere? Thanks to an offshoot of the Taiwanese firm Glacialtech,

which makes PC power supplies and heatsinks, PCSTATS has put together a virtual

factory tour of its GlacialLight LED lighting plant situated in DongGuan, China.

As it happens, the computer industry is well suited to

LED light manufacturing. The process isn't a whole lot different than making a

computer motherboard, so follow along as PCSTATS takes you

on a guided tour of a LED lighting factory!

LED technology has been around since the late 1960's, and for the

first 40 years LEDs were primarily used in electronics devices to

replace miniature light bulbs. Within the last decade or so, advances

in the technology finally boosted light output high enough for LEDs to

begin to seriously compete with the light bulb - technology that's a +100

years old.

Brief History of Light Emitting Diodes

The word LED is actually an acronym for Light Emitting

Diode, a solid state electrical circuit that, in simplified

terms, generates light by the movement of electrons in a semiconductor material.

LED lights are

very

energy efficient, but several challenges need to be overcome

before most people will be happy to part with

inexpensive incandescent and relatively energy efficient compact fluorescent light bulbs.  The foremost

is quality of light. Compared to a regular incandescent light bulb, white

light produced by LEDs can have an unpleasant bluish or

purple tint.

The foremost

is quality of light. Compared to a regular incandescent light bulb, white

light produced by LEDs can have an unpleasant bluish or

purple tint.

As with most technologies, each successive LED generation improves light quality, the amount

of light output per Watt, and reduces cost and heat. The

age of solid state general purpose lighting is

quickly approaching.

Crosswalk Signs to Architectural

Lighting

Glacialtech make computer CPU heatsinks and PC power supplies, so

it's not surprising that the company recently expanded into the growing

market for solid state LED lighting products.

In North America LED architectural lighting is just beginning to

take hold, but if you've visited Hong Kong, Shanghai or any other major city

in China you will have witnessed multi-coloured LED lighting decorating every skyscraper on

the horizon... Not to mention those friendly green digital count-down crosswalk signs,

store lighting, and countless red vehicle tail lights.

Building-sized LED lighting for

full motion advertising in Shanghai, China.

Parts of an LED Light

An LED light consists of four essential components; the LED circuit board, a

heatsink and power supply, and shell.

The lights start out as bare printed circuit boards (PCB) and high luminance

LED elements arrive from separate factories which specialize in making those

components. LED elements themselves create a bit of heat, so the PCB used in

lighting fixtures is a little special. Instead of the standard non-conductive

sandwich of epoxy and fiberglass, the circuit board is laid out on a thin

sheet of aluminum which acts as a heatsink.

The aluminum PCB used in LED lighting

is coated with a non-conducting material and conductive copper trace

lines to form the circuit board. Solder paste is then applied in

the right places and then SMT machines (Surface Mount Technology) place

the tiny LED elements, driver ICs and other components onto the board at ultra high

speeds.

The aluminum PCB used in LED lighting

is coated with a non-conducting material and conductive copper trace

lines to form the circuit board. Solder paste is then applied in

the right places and then SMT machines (Surface Mount Technology) place

the tiny LED elements, driver ICs and other components onto the board at ultra high

speeds.

The round shape of a traditional light bulb means that most LED

printed circuit boards are circular, so for ease of handling several of

the smaller circular PCBs are combined into one larger

rectangular PCB that automated SMT machinery can handle. Think of it like

a cupcake tray moving from one machine to the next

along a conveyor belt, then at the end the individual cupcakes are snapped free from the

tray.

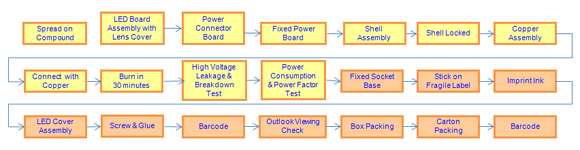

|

The manufacturing

steps.

|

Once the larger sheets of LED circuit boards have passed

through a solder reflow oven (a hot air furnace that melts the solder paste),

they are broken up into the individual small circuit boards and power wires

manually soldered on.

The small power supply

housed in the body of the light bulb goes through a similar process, or

may be delivered complete from another factory. In either case, the manufacturing

steps are the same; first the PCB passes through SMT lines, then it goes to a manual DIP assembly line where a long row of factory workers

add one component at a time.

LED Light bulb Factory Tour

Follow along as GlacialLight factory works assemble a BR30 LED spotlight. The light draws about 10W and

outputs between 360lm to 540lm depending if 6W or 9W LED elements are used.

Colour temperature is rated at 3000K or 6000K, depending on the model. Life

expectancy is 35,000 hours.

|

Surface Mount Device (SMD) Line.

|

Keep up, the tour continues next page as we see the LED modules being

assembled into a PAR30 LED light bulb...