With Intel's socket 775 processor formfactor, Intel has accomplished a couple of noteworthy things. The first was to substantially reduce the complexity

and cost of manufacturing its processors; removing the vulnerable and

delicate interface pins from the bottom of CPUs meant that manufacturing losses

and customer returns both dropped significantly for Intel.

The second accomplishment was, unfortunately, to increase the complexity

and risk involved in installing one of the new 775 processors into a

motherboard.

By removing the pins from each CPU, Intel off loaded the responsibility

of adding interface pins to motherboard manufacturers (who also now

have to deal with returned merchandise and angry customers with bent

socket pins). This is a bad thing for Intel users in general, as now

the motherboard is the most likely component to be damaged during an

installation gone bad, and compared to Intel many motherboard manufacturers

are notoriously unreliable in providing replacement parts.

Here at PCSTATS, we had our share of troubles and frustration

with the new installation method before we got completely used to it, so we

thought we'd run off a quick guide illustrating the procedure for the

benefit of our readers. If you are planning on building a Intel based computer

anytime soon, bookmark this PCSTATS Beginners Guide.

The LGA 775 processor chip and socket

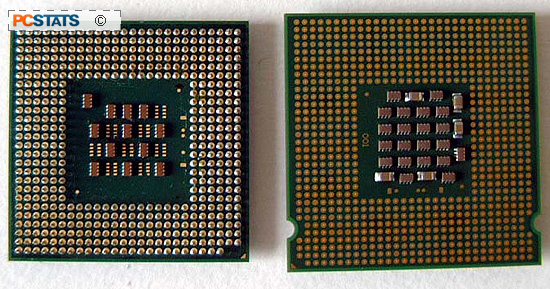

As you probably know by now, Intel processors have no pins

at all. Instead they merely have the electrical contacts where the

pins (which are now built into the socket on the motherboard) will touch.

While the lack of pins makes these chips much less fragile, the bottom of

the processor should not be touched, as the contacts can be damaged.

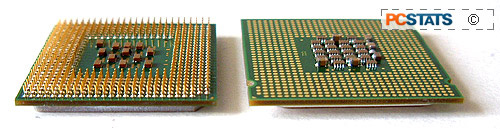

On the left above is the previous socket 478 style Intel

processor, at right the current socket 775 style pinless processor. In all other physical respects the new chips are unremarkable, so

let's move on to the socket.

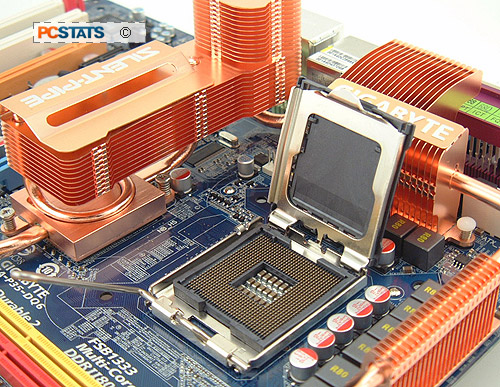

As you can see, the array of pins which connect the processor to the

motherboard are now attached to the socket and they are very

fragile and easily bent. All socket 775 motherboards feature the metal

shim (load plate) pictured above, which serves the dual purpose of

locking down the processor once it is installed and protecting the pins from harm

when it is not. Most boards also implement a protective

plastic cover which fits over the load plate when no processor is present, hiding the pins

completely. The lever secures the shim in place, holding the processor

when it is installed.

It is extremely important that the processor be installed slowly, carefully

and vertically into the socket, and removed the same way. Any careless

handling will damage the pins, and may leave you with a useless

motherboard.

Now its time to describe exactly how to install one of

these chips correctly. It's not the hardest thing in the world, but it pays to be careful and follow a predetermined set of

steps.