Apart from the warehouse, the production line floors also

contained large storage areas, some with racks of component roll cartridges for the SMT

machines and some with sealed, moisture-proof cabinets for expensive core-logic components. We

also got to see a technician programming BIOS chips prior to their

installation.

Fine

motivational strategy... 'lesser' mistakes are acceptable

|

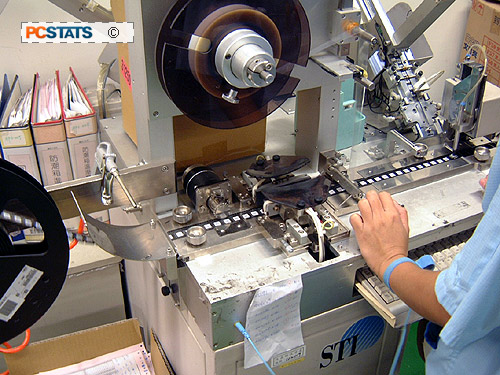

Automated BIOS chip and

IC storage cabinet. Chips are stored in

rolls to be used in SMT machines, and inventory is computer controlled.

|

Given the vast number of tiny electric parts that go into

a motherboard, we had envisioned buckets of resistors, capacitors, and IC's.

However, given the speed and automation of the factory machines, the time it

would take for a machine to pick out a 1mm square resistor from a pile, oriented

it correctly, and place it on the PCB would be too long and inefficient. Thus,

all components are stored on film reels, each contained it a little plastic

cup. The components are pre-oriented, and the high-speed automated machines can

handles these parts with machine-gun like speed.

More storage

for other SMT components |

Programming,

labeling, and testing

BIOS chips |