The slots, sockets, connectors and capacitors that were plugged into the board on the manual assembly

line now need to be soldered to the motherboard. Manual soldering would be

too time consuming, so Gigabyte makes use of a special

soldering process called wave soldering.

This imposing piece of mechanics is the final step on

the conveyor belt that runs through the manual assembly lines. It runs the

bottom of each motherboard through a 'wave' of liquid solder (induced

by flowing the molten solder over a raised ledge) at a

precise height, so that the metal leads of the plugged-in components are

coated with solder. Each board passes through this wave for 2-4 seconds, after which it is

allowed to cool naturally so the solder can solidify around the contacts.

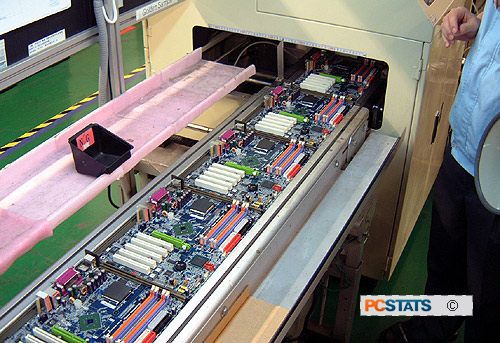

About to go

into the solder wave machine. |

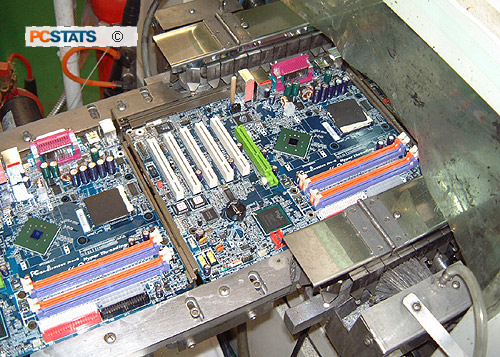

Note the lead

weight on the socket. This stops it floating up in the solder

|

Larger sockets sometimes have a tendency to float up a

little, so small lead weights are used to hold these sockets down.

The wave

solder reflow machine |