Gigabyte out sources the PCBs (Printed Circuit Boards) it uses for its motherboards to a

PCB manufacturer. These arrive already etched with the necessary circuit

traces, pre-coloured and pre-drilled with the holes that are needed to insert

components like the CPU socket and PCI slots. Other than this though, they

are completely bare, containing no components or solder.

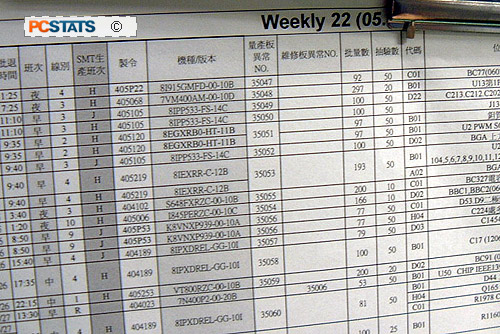

Weekly

production sheet identifying the motherboard models

|

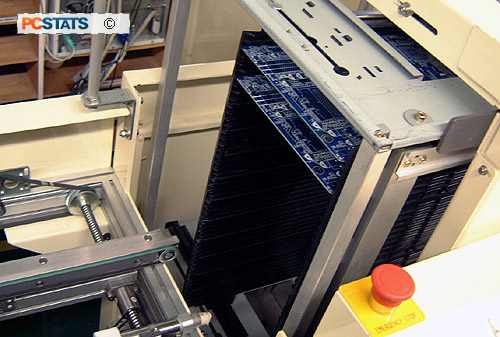

These bare PCB boards are stored on racks and loaded into the automated feeder for the

DEK Infinity solder paste printer to start their journey towards becoming completed

motherboards.

Solder Paste Screen Printing

Before being sent to the SMT (Surface Mount Technology) machines

that will mount chips and resistors onto the PCB, each motherboard must be

prepared by solder paste printing, a technique which involves spreading

solder paste over a nickel sheet, laser cut to correspond to

the motherboard being assembled. This nickel sheet 'screen' is then moved

into the printer and the motherboard positioned precisely under it. The paste is

distributed over the screen by the printer so it is squeezed through

the holes in the nickel sheet to adhere to the motherboard underneath in

precise areas.

The DEK

Infinity solder paste screen printer (left)

|

Mixing and

applying the solder paste to the nickel screen

|

The solder paste: particles of solder suspended in

flux |

After having the solder paste applied, the bare

PCB boards are stacked into an automated vertical storage rack called

a PCB Buffer Loader, until ready to be passed through to the SMT

assembly machine.

Solder

printed motherboards awaiting the SMT process

|