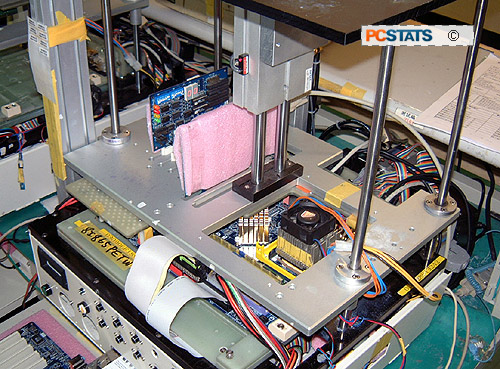

This test is designed to establish that each motherboard

works correctly under 'normal' operating conditions. Each testing station has a special

rack that is lowered pneumatically, automatically plugging in the

test PCI and videocards, and port 80 card while the technician attaches IDE cables, memory

and processor and heatsink manually. Interestingly, the test CPU is attached to

the bottom of the heatsink with adhesive, and the

entire assembly is just placed into the socket in one quick

movement.

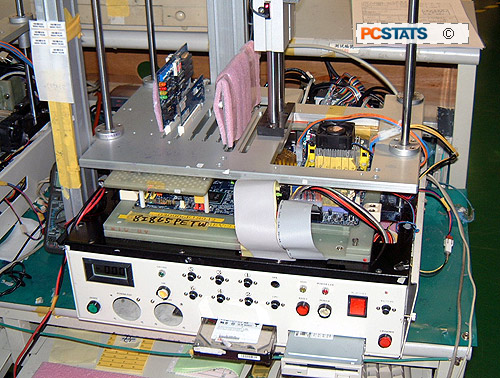

A second pneumatic connector attaches parallel, serial, PS/2 and USB connectors as

well as video sound and networking jacks to the rear I/O panel

of the motherboard automatically in one go. The tester

adds hard drive, CD and floppy cables attached to components hard mounted to each

test station.

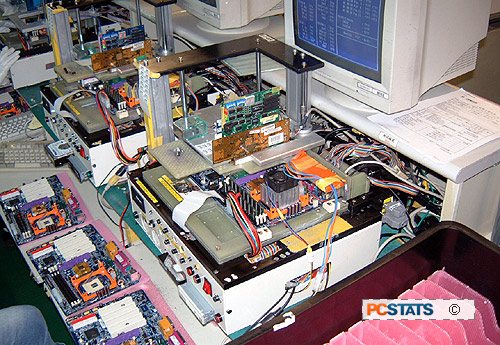

Gigabyte

motherboard test center |

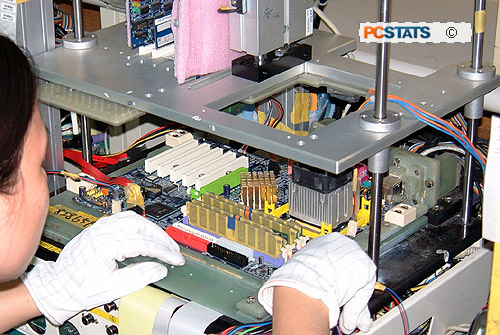

Hooking up each motherboard for testing takes only about a minute. Once set

up, the motherboard is powered on and booted into a DOS test program and the

functionality of every component and peripheral is confirmed.

Every motherboard

is tested for functionality before moving off to the final stage of

testing.

Pneumatic test rack

clamps down onto completed motherboard to reduce worker fatigue from

installing videocards and PCI

Port-80 test cards all day long

|

Note the

drives mounted into the test rack. |

A second

pneumatic arm holds connectors for the rear I/O ports, right

|

The entire

test bed |

Each worker handles two test stations at once, while the

second is being set up the first is left to run a series of automated tests.