Once the motherboards are fully stress tested, they are

ready to be packaged and shipped. Gigabyte, like most manufacturers, orders their motherboard

boxes from a separate manufacturer and sends them off to be printed.

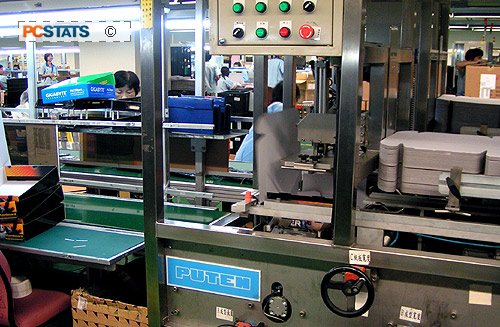

Once the printed boxes are received, they pass through a machine which

folds and shapes them correctly, then it's down another manual assembly line

where workers place each tested motherboard into its box.

In go any promotional stickers, the cardboard divider, antistatic foam, software

and other peripherals, then they are sent off to be packed into

shipping boxes. The box packing machines are automated, wrapping packing plastic strips around

each box faster than the human eye can see!

Adding

stickers and accessories to the box |

Box shaping

machine |

Newly shaped

boxes ready for motherboards |

Reference

board for motherboard box contents

|

Sealing boxes

with plastic binding |

Stacked boxes of

motherboards ready

for shipping around the world |

We hope you've enjoyed PCSTATS visual tour of

how motherboards are made, and have a better idea of how much work goes

into every component of your system!

Our thanks goes out to Gigabyte

for the unprecedented access they gave PCSTATS to photograph every square inch

of the Nan-Ping factory in Taipei, Taiwan.